Minerals are essential components of the technological world. From the silicon used to form the circuits in electronics to the iron found in steel infrastructure, minerals play a crucial role in the advancement of technology. Rare earth elements, such as neodymium, are used in small amounts but are essential for many high-tech products such as mobile phones, lasers, and computers.

In addition to the minerals used to form the components of technology, minerals are also essential for powering technology. Fossil fuels derived from organic materials, such as coal and oil, are used to generate electricity for powering technology. Renewable energy sources, such as solar, hydroelectric, and wind, also utilize minerals, such as the aluminum used in solar panels and the copper used in wiring. Thus, minerals are essential for the production and powering of the technology that shapes our world.

Copper

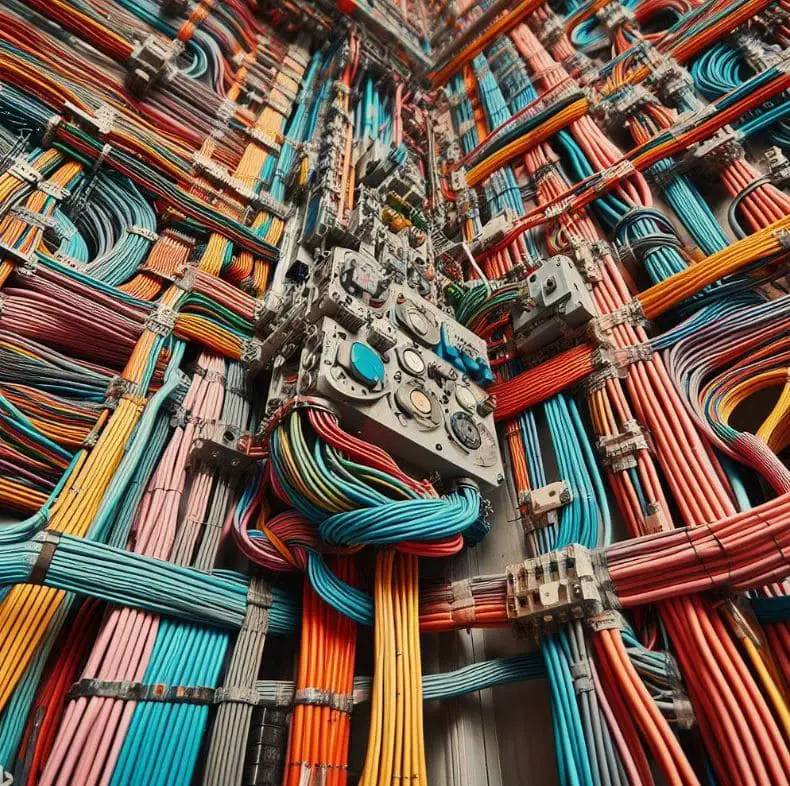

Copper is an essential component of many electrical systems, from wiring to printed circuit boards to electric motors. Wiring made of copper is the most common form of electrical wiring, as it is a strong and reliable conductor of electricity. Copper wiring is also resistant to corrosion and can be easily bent, making it an ideal material for wiring. Printed circuit boards (PCBs) are also commonly made from copper, as the metal is an excellent conductor of electricity and can be easily etched into intricate patterns.

Electrical Wiring

To further explore the use of copper, we turn to electrical wiring. Copper is an ideal material for wiring due to its excellent electrical conductivity and malleability. This makes it easy to shape and form into a variety of sizes and shapes. Additionally, copper wires are resistant to corrosion and are relatively inexpensive. Copper wiring is used in a variety of electrical applications, including residential wiring, industrial wiring, and automotive wiring.

Copper wiring is used to power a variety of electrical devices, from light fixtures to large appliances. Copper is also used in wiring for electric motors. Motors are typically powered by copper wiring, which is used to transfer electrical energy to the motor, allowing it to rotate. Copper wiring is also used in the construction of electrical circuits, such as printed circuit boards. These boards are composed of multiple copper layers, which are used to create a circuit and provide electrical connections between components.

Copper wiring is also used in telecommunications. Copper wires are used to connect telephone systems, computers, and other communications systems.

Printed Circuit Boards

Shimmering in the light, copper is the backbone of electronics, playing an important role in printed circuit boards (PCBs). PCBs are the backbone of electronic components, allowing them to connect and interact with each other. PCBs are made up of layers of copper, which are sandwiched between layers of a non-conductive material, such as fiberglass, plastic, or ceramics. This alternating layer of copper and non-conductive material allows electricity to flow and signals to be transmitted.

The copper in PCBs also provides heat dissipation, helping to regulate the temperature of the board. By creating a low resistance path, copper helps to prevent the buildup of heat, thus reducing the risk of damage to the board and the components it contains. In addition, copper is lightweight and highly durable, making it ideal for use on PCBs as they are often exposed to a wide range of environmental conditions.

Electric Motors

Moving beyond its application in electrical wiring and printed circuit boards, copper is also a key component in electric motors. Copper is essential in electric motors because it is an excellent conductor of electricity, and it can withstand high temperatures without losing its properties. Copper’s superior conductivity also allows smaller motors to be used, which helps to reduce the overall cost of production.

In addition, copper is highly malleable, making it easier to shape and form into the desired components needed for an electric motor. This malleability also allows for a more efficient manufacturing process. Furthermore, copper is a durable material that is able to withstand long-term use, making it an ideal choice for electric motors.

Given its numerous advantages, it is no surprise that copper is the most popular material in the production of electric motors. Its superior conductivity and malleability, combined with its durability, make it the ideal material for electric motor manufacturing.

Gold

Gold is a valuable metal used in a variety of industries. Its properties of malleability, corrosion resistance, and electrical conductivity make it ideal for electronics and electrical contacts, medical devices, and the aerospace industry among others. Gold is a key material for electrical contacts, due to its low contact resistance, and ability to resist corrosion. It is also used for medical devices, such as implants and prosthetics, due to its biocompatibility and ability to resist corrosion. In aerospace, gold is used for wiring, connectors, and thermal control systems due to its electrical and thermal conductivity.

Electronics and Electrical Contacts

Gold is well known for its excellent conductivity, making it an ideal choice for electrical contacts. In fact, gold is the preferred material for many electronics and electrical contacts due to its superior conductivity and its ability to resist corrosion and oxidation.

Gold is used in a variety of applications in the electronics and electrical contacts industry, including connectors, switches, relays, and circuit boards. Gold is also used in the manufacture of various types of sensors, such as accelerometers and gyroscopes. Gold is also used in the manufacturing of various types of contactors, such as those used in automotive applications.

Additionally, gold is often used in the fabrication of electrical contacts that are intended for long-term use. Gold is known for its excellent durability, making it an ideal choice for highly reliable electrical contacts.

Medical Devices

Gold is known for its malleability and corrosion resistance, making it a popular choice for jewelry, electronics and electrical contacts, medical devices, and even aerospace applications. In particular, gold’s unique properties make it a highly sought-after material for medical device manufacturing.

Gold’s inertness and resistance to corrosion make it ideal for medical implants and devices, as it is less likely to cause an adverse reaction in the body. Additionally, gold is non-toxic, allowing it to be used in a range of medical treatments. For example, gold nanoparticles have been used to deliver drugs to target cancer cells. Gold is also used in radiotherapy, as its high atomic number makes it able to absorb radiation.

Gold is also used in dental applications, as it is highly malleable and can be shaped into a variety of forms.

Aerospace Industry

After uncovering the unique properties of copper, such as its malleability and ductility, let’s turn our focus to Gold. Gold is renowned for its strength, durability, and malleability; it is also known for its ability to resist corrosion and tarnishing. These unique properties make it ideal for a variety of applications in the Aerospace industry.

For instance, gold is used in electronics and electrical contacts, as it can conduct electricity with minimal resistance. Gold is also commonly used as a conductor in medical devices such as pacemakers, due to its superior conductive properties. Finally, in the aerospace industry, gold is used as a coating material on satellites and other spacecraft, as it helps to protect against the harsh environmental elements in space.

Another advantage of gold in the aerospace industry is its durability and resistance to corrosion. Gold can withstand extreme temperatures and will not rust or tarnish easily, even in extremely harsh environments.

Lithium

Lithium is a lightweight alkali metal that has a variety of applications. Lithium-ion batteries are commonly used in consumer electronics, such as cell phones, tablets, and laptops. These batteries are also used in spacecraft components, as they provide a reliable and durable source of energy. Lithium-ion batteries are also used in electric vehicles, as they provide the necessary power to propel the vehicle forward. Lithium-ion batteries are more efficient than traditional lead-acid batteries, and they are also lighter and more compact.

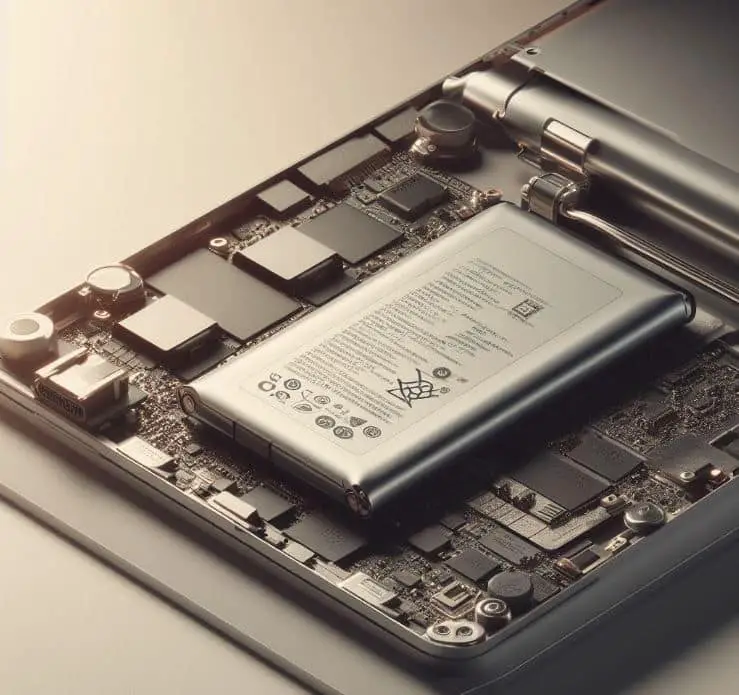

Lithium-Ion Batteries

Gold’s history has been intertwined with human civilization for millennia, but lithium has recently emerged as a critical element for modern technology. From powering lithium-ion batteries to spacecraft components to electric vehicles, lithium has become an invaluable resource. Lithium-ion batteries have become ubiquitous with modern technology, from powering smartphones and laptops to electric vehicles. The reason for lithium’s success is its ability to store large amounts of energy in a small amount of space. This has allowed batteries to become smaller and lighter without sacrificing power and capacity. Lithium’s unique properties also allow it to charge and discharge quickly, making it ideal for applications such as electric vehicles that require a large amount of energy to be stored. Additionally, lithium-ion batteries have a long lifespan, with many batteries lasting for several years without any noticeable decline in performance.

The advantages of lithium-ion batteries make them an invaluable resource for modern technology. They are an essential component of electric vehicles, as they provide the power needed to drive the vehicle.

Spacecraft Components

After its discovery in the 19th century, gold had been highly sought after for its uses in jewelry, coins, and other applications. However, lithium has become a game changer in the 21st century. This element has been used in various industries, including the development of lithium-ion batteries and components for spacecraft.

Lithium-ion batteries are the most popular type of batteries used in electronics due to their high energy density and low self-discharge rate. It has become the battery of choice for most electronic devices due to its reliability and longevity.

Spacecraft components are essential for the success of any mission. Lithium has been used in many spacecraft components, such as its fuel, guidance systems, and radiators. Lithium has the ability to store large amounts of energy, and it is used to power the spacecraft’s internal systems, as well as to fuel the spacecraft itself. It is also used to provide guidance systems and communications systems.

Electric Vehicles

With its ability to store and deliver energy, Lithium has revolutionized the way we power electric vehicles. In the last decade, Lithium-ion batteries have become the main source of energy for electric vehicles, and their use has been growing exponentially. These batteries offer a number of advantages, such as their lightweight design, their high energy density, their low self-discharge rate, and their long life cycle.

This has led to electric vehicles becoming increasingly popular as a viable alternative to petrol and diesel cars. According to a study by the International Energy Agency, the number of electric vehicles on the road in 2019 is expected to exceed 8 million, up from 1.1 million in 2015. This represents a remarkable growth rate of over 40% per year.

Electric vehicles have a number of benefits over petrol and diesel cars, including being cheaper to maintain, more fuel-efficient, and more eco-friendly. They also produce no tailpipe emissions, which helps reduce air pollution and greenhouse gas emissions.

Cobalt

Cobalt is a versatile element with multiple uses across various industries. Lithium-ion batteries are one common use, as cobalt is a key component in the production of these batteries. In particular, cobalt is used in the cathode of the battery and is essential for its ability to store and release energy. Medical implants also rely on cobalt alloys. These alloys are highly resistant to corrosion and can be used in joint replacements, as well as in prosthetics. Finally, superalloys consist of cobalt, as well as other metals such as chromium and molybdenum.

Lithium-Ion Batteries

Lithium has become a popular choice in many industries for its various uses, particularly when it comes to lithium-ion batteries. However, the use of lithium-ion batteries does come with some risks. Lithium-ion batteries are highly flammable, meaning if not handled correctly they can cause fires and explosions. Furthermore, when used in medical implants, such as pacemakers, the risk of fire is even greater. To address this risk, many companies have begun using materials such as cobalt and superalloys to make their lithium-ion batteries safer.

Cobalt is a metal that has been used for centuries in the production of various alloys and is now being used in the production of lithium-ion batteries. Cobalt is known for its ability to increase the energy density of batteries, meaning it can hold more energy in a smaller space. This makes it ideal for use in medical implants, where the size of the battery needs to be as small as possible.

Medical Implants

Having discussed the use of lithium in Lithium-ion batteries, it is now time to turn to its use in medical implants. Medical implants are becoming increasingly popular, owing to their ability to improve patient quality of life and extend life expectancy. These implants are often made from superalloys, which are engineered materials that contain lithium. Superalloys are used in medical implants due to their biocompatibility and ability to resist corrosion and fatigue.

The most common medical implants containing lithium are pacemakers and prosthetic joints. Pacemakers are used to regulate heart rate and are powered by rechargeable Lithium-ion batteries. To ensure a medical device lasts a long time, it must be corrosion-resistant and have a low weight. Superalloys containing lithium meet these requirements and are therefore used in pacemakers.

Prosthetic joints are also made from superalloys containing lithium. These implants have to be durable and lightweight and must be able to withstand physical stress.

Superalloys

Harnessing the power of lithium, cobalt is a vital component in the creation of superalloys. These alloys, which are made of a combination of metals, are used in industries that require high-performance materials. From aerospace engineering to medical implants, superalloys are relied upon for their strength, durability, and corrosion resistance.

Cobalt is a key component in the formation of superalloys, as it imparts these materials with superior resistance to wear and fatigue. In particular, cobalt is an important element in the creation of stainless steel and other stainless alloys, which are commonly used in aircraft engines and medical implants. Cobalt also helps to create other materials that are resistant to high temperatures and corrosive environments.

The use of cobalt in superalloys has been steadily increasing, as the demand for these materials is growing due to their versatility and strength.

Graphite

Graphite is a critical component in many industries. It is used in lithium-ion batteries, nuclear reactors, and heat dissipation. Lithium-ion batteries use graphite anode material to store energy. Graphite’s structure allows lithium ions to move within it, resulting in higher energy density and increased capacity. Graphite’s high thermal conductivity also helps to dissipate heat generated during charging and discharging cycles. In addition, graphite’s low reactivity is beneficial in preventing side reactions between the electrolyte and the anode material.

Lithium-Ion Batteries

Astonishingly, Lithium-ion batteries have been a game-changer over the past few decades. Not only have they revolutionized the way we power our lives, they have also become the go-to choice for many industries, such as the automotive industry. The technology has made it possible to power electric cars, which are a much more sustainable choice than petrol-powered vehicles.

Curiously, Lithium-ion batteries have some unique properties that set them apart from other types of batteries, such as graphite. For instance, they are much lighter and more efficient than traditional batteries, making them ideal for small electronic devices. Furthermore, Lithium-ion batteries are able to store a large amount of energy in a small package. This makes them ideal for powering electric cars, as they can travel further on a single charge.

In addition, Lithium-ion batteries are incredibly safe. They are designed to prevent overheating, and they do not contain any toxic materials.

Nuclear Reactors

Moving on from Cobalt, Graphite is another element that is widely used in the creation of Lithium-ion batteries, as well as in nuclear reactors. Nuclear reactors are large-scale plants that use nuclear fission to generate electricity. They play a vital role in the production of nuclear energy, which is used to power the majority of the world’s electricity grid. Nuclear reactors consist of three primary parts: the fuel, the moderator, and the control rods. The fuel is typically uranium or plutonium, the moderator slows down the neutrons, and the control rods provide a means of regulating the speed of the reaction.

The primary advantage of nuclear reactors is the production of large amounts of electricity with a relatively small quantity of fuel. The fuel can last for decades, providing a significant source of long-term energy, which is why nuclear reactors are often seen as an efficient and cost-effective energy source.

Heat Dissipation

Having discussed Cobalt and its role in Lithium-ion batteries, let us now turn our attention to heat dissipation. Heat is a byproduct of many electrical processes, particularly Nuclear reactors. As such, it is of utmost importance that effective mechanisms for heat dissipation are put in place. One of the most effective methods for heat dissipation is the utilization of Graphite.

Graphite is a material with excellent heat transfer capabilities. It is composed of a series of layers of carbon atoms, which creates a porous structure. This porous structure allows for high levels of heat exchange, making it ideal for use in heat dissipation systems. Moreover, it does not corrode or react to other materials, making it a safe and reliable material for use in many applications.

Heat dissipation systems are essential for keeping temperatures at a safe and manageable level. As such, these systems must be well-designed and efficient.

Aluminum

Aluminum is an incredibly versatile and lightweight metal that makes it an ideal choice for a variety of applications. It is used in smartphone casings, as its lightweight strength makes it the perfect material for protecting delicate electronic components. It is also used in aircraft frames, as its low weight and strength help to reduce fuel consumption and improve performance. In addition, aluminum is also used in the construction of building materials, such as siding and roofing, as it is a strong and durable material that is capable of withstanding the elements. Its corrosion-resistant properties also make it an ideal choice for outdoor applications.

Smartphone Casings

The conversation shifts to aluminum, a lightweight, corrosion-resistant metal alloy. Its malleability and ability to be cast into different shapes make it a popular choice for many industries. In the smartphone industry, aluminum is commonly used in the construction of casings. It’s popular because of its durability, low weight, and ability to dissipate heat.

Aluminum is extremely resistant to corrosion, making it an ideal material for cases that are exposed to the elements. This metal alloy has a higher tensile strength compared to other materials like plastic, so it can better withstand impacts and drops. In addition, it has good thermal conductivity that helps dissipate heat away from sensitive components.

The popularity of aluminum in smartphone casings has led to many manufacturers offering different colors and finishes. Companies have used different coatings, such as anodizing and powder-coating, to create a range of colors and textures. Aluminum can also be machined to produce a range of finishes from brushed metal to polished chrome.

Aircraft Frames

Swapping out Graphite for Aluminum, we find ourselves looking at a material that has been a staple of the aviation industry for decades. Aluminum is a lightweight yet strong metal used to make aircraft frames and is one of the most commonly used metals for building. It is also used in smartphone casings and is the most efficient material for dissipating heat.

Aircraft frames constructed from Aluminum provide many advantages. The low weight of the metal means fewer stress points in the structure, providing greater rigidity and a resulting increase in safety. Additionally, it can be formed into components with complex shapes, such as those found in modern aircraft. Its resistance to corrosion, a major concern for aircraft frames, is also a major advantage of Aluminum.

The cost of Aluminum is also a major factor in its popularity for aircraft frames. It is relatively inexpensive when compared to other metals, and the cost of working with it is also comparatively low.

Zinc

Zinc is used in a wide variety of industries and products, including galvanizing steel, batteries, and biomedicine. Galvanizing steel involves coating steel with a thin layer of zinc to protect it from corrosion. This is often used in roofing, fencing, guardrails, and other structures. Batteries incorporate zinc into their cathodes, providing an inexpensive, long-lasting source of power. Zinc is also used in biomedicine, such as to treat skin conditions and in wound healing. Zinc has long been recognized for its antibacterial properties, making it an ideal choice for medical applications.

Galvanizing Steel

Having examined aluminum, let’s now turn our attention to zinc, a metal widely used in galvanizing steel. Galvanizing is a process that coats metal with a layer of zinc to protect it from corrosion. This process is used to protect a variety of steel materials, including those used in the automotive, construction, and appliance industries.

The zinc layer acts as a sacrificial anode, meaning it corrodes in place of the steel beneath it. This process prevents rust and other forms of corrosion from damaging the steel and the products that contain it. As an added benefit, the zinc layer gives steel a glossy, attractive appearance.

The galvanizing process is relatively simple and cost-effective, making it a popular choice for protecting steel products. Hot-dip galvanizing is the most commonly used method and involves dipping the steel into a molten zinc bath. After the steel has cooled, a coating of zinc is left on the surface and the product is ready for use.

Batteries

Having explored the incredible properties of aluminum, let’s take a look at another metal often used in industrial applications: zinc. Zinc is a versatile metal, used in many industries, from automotive to construction. One of the ways in which zinc is used is in galvanizing steel, a process that protects the steel from corrosion.

But zinc is also used in another important application: batteries. Zinc-air batteries are a type of rechargeable battery that are used in a variety of electronic devices. They are often used in medical devices such as hearing aids, and they are also used in some types of cars. The zinc-air battery is highly efficient, making it a great choice for many applications.

Zinc also has applications in biomedicine. For example, zinc supplements are often used to treat a variety of conditions, such as zinc deficiency, which can lead to health problems.

Biomedicine

Having considered the properties of aluminum, it is now time to investigate the characteristics of zinc. Zinc is a valuable metal in many industries, and particularly in biomedicine. Zinc is essential for developing enzymes and proteins, and is used to control inflammation, maintain the integrity of cells, and regulate gene expression. It has been used to treat bacterial infections, acne, and common colds. Zinc has also been found to be useful in the treatment of cancer, as it has been shown to reduce the spread of cancer cells and increase the production of immune cells.

In addition, zinc has been used to treat chronic wounds, such as ulcers, as it has been found to accelerate healing and reduce inflammation. Furthermore, its antioxidant properties have been found to be beneficial in the treatment of cardiovascular diseases, by reducing oxidative stress and improving endothelial function.

Silver

Silver has many applications, including electrical contacts, solar panels, and photography.

Electrical contacts are sometimes made with silver, as the metal is known to have excellent electrical conductivity and corrosion resistance. Silver contacts are typically used in aerospace, defense, and medical applications.

Solar panels also use silver, as it is one of the best materials for reflecting and conducting sunlight. In addition, silver is used to create the busbars that connect solar cells to each other and to the external circuit.

Photography is another area where silver is used.

Electrical Contacts

Having discussed the properties of zinc, it is now time to turn our attention to silver and its many uses. One of the most common applications of silver is in electrical contact, where its superior conductivity makes it the ideal choice for many electrical components. Silver is known for its low contact resistance, meaning that electricity can pass through it with minimal resistance. This makes it an ideal choice for use in high-voltage applications, such as circuit breakers and power supplies. In addition, silver is highly resistant to corrosion, meaning that it can be used in a variety of environments without worrying about the contacts becoming damaged over time.

Silver is also used in solar panels, where its high reflectivity helps to maximize the amount of sunlight that the panels can absorb. Silver is also used in many different types of photography. For example, silver halide crystals are used in film photography, and silver is also used in the production of photographic paper.

Solar Panels

Following the discussion of zinc, let us now examine the role of silver in the context of solar panels. Silver is used as an electrical contact in solar cells. It has a low contact resistance and is highly conductive compared to other metals such as copper and gold. Additionally, silver has a high reflectivity which helps to reduce the amount of light absorbed by solar cells, thus allowing for greater efficiency.

Solar panels are composed of layers of photovoltaic cells, with silver electrical contacts used to connect them together. The silver electrical contacts are usually applied using a silver paste, which consists of silver powder and an organic-based carrier. This silver paste is then fired onto the solar cells in a process called screen printing, which helps to make the electrical connections between the cells.

Silver’s electrical conductivity and low contact resistance make it an ideal choice for use in solar cells. Its high reflectivity reduces the amount of light absorbed by the cells and increases the efficiency of the solar panel.

Photography

Having discussed the properties of zinc, let’s now move on to another important metal – silver. Silver is an important component in electrical contacts, solar panels, and photography. In particular, its unique reflective properties make it an ideal choice for photography. It is particularly valuable when it comes to capturing photos in low light settings since it helps to reduce the amount of light required to take the perfect shot. This is why silver is a popular choice for professional photographers looking to capture stunning images.

Silver often produces vibrant colors and sharp details, providing a high-quality result. It is also highly durable and can be used in a range of environments without risk of damage. Furthermore, silver is known for its ability to capture a wide range of colors, making it a great option for color photography.

Silver is also known for its ability to capture fine details, such as facial features, that can be lost when using other metals. *With the right equipment and settings, silver can produce stunningly clear images with crisp details.

Tungsten

Tungsten is a metal with properties that make it a great choice for a variety of applications such as filament wires for incandescent bulbs, cutting tools, and drills. Its strength and toughness make it ideal for use in filament wires, where it can withstand the intense heat and pressure of an electrical current. Its high melting point also makes it ideal for cutting tools and drills, where it can withstand the high temperatures necessary for drilling and cutting. Additionally, its high density makes it useful for X-ray tubes, where it can absorb and focus X-rays.

Filament Wires for Incandescent Bulbs

Moving away from the discussion of gold, let us take a look at tungsten. Tungsten is a metal that is known primarily for its strength and durability, and this makes it an ideal material for use in many everyday items. One of the most common uses for tungsten is in the manufacture of filament wires for incandescent bulbs. These tungsten wire filaments are able to withstand extremely high temperatures while still maintaining their structural integrity, allowing them to produce light for an extended period of time.

Tungsten is also used to make cutting tools and drills, due to its hardness and ability to retain a sharp edge. It is also used in the production of X-ray tubes, as its density and heat-resistant properties make it an ideal material for containing high-energy X-rays. Furthermore, tungsten is also used in nuclear reactors, as its high melting point makes it a suitable material for containing radioactive materials.

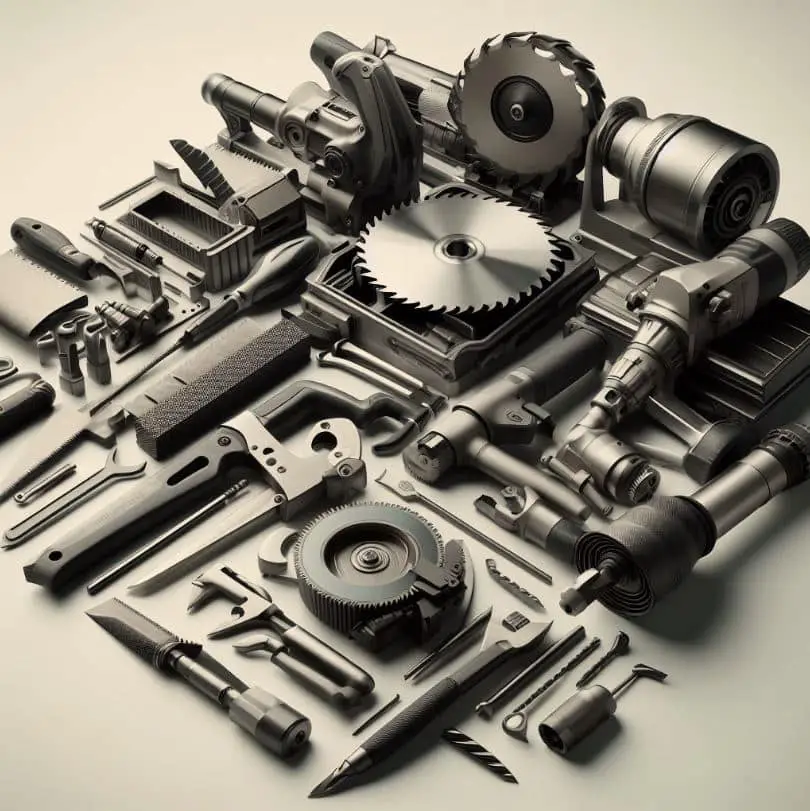

Cutting Tools and Drills

Taking the discussion of gold forward, tungsten is another element that has been used for a variety of applications. A key use of tungsten is in cutting tools and drills due to its ability to work at high temperatures without significantly softening or weakening. It also has a high melting point and is very hard, making it an ideal material for the manufacturing of cutting tools.

Tungsten has been used for the production of cutting tools such as drills and taps. It is also used for the production of filament wires for incandescent bulbs due to its high melting point. The combination of its hardness and high melting point makes it an ideal material for these applications.

Tungsten cutting tools are known for their durability and can be used for a variety of applications, such as drilling, cutting, and tapping. These tools are able to withstand high temperatures and do not easily break or wear down.

X-Ray Tubes

Having talked about gold, let’s now shift to another metal that is also used for a number of purposes: tungsten. Tungsten is a hard, grayish-white, metallic element that is widely used in filament wires for incandescent bulbs, as cutting tools and drills, and in X-ray tubes. X-ray tubes, in particular, are of great importance to the medical field.

Tungsten is a dense metal that can be used to form an electron beam in X-ray tubes. This beam can then be used to generate X-rays for medical imaging. Due to its high atomic number, tungsten is ideal for this purpose as it can produce the highest quality of X-rays. In addition, its high melting point makes it durable and long-lasting, which makes it a great choice for medical use.

Tungsten has also been found to be a great alternative to lead, which has traditionally been used for medical imaging.

Silicon

Silicon is a semi-metallic chemical element with a wide range of applications in our modern world. It is the second most abundant element and is found in many materials. It has been used in the manufacture of Microchips and Semiconductors, which are essential components in electronic devices. Silicon is also used in the production of Solar Cells, which is a type of energy-generating device that converts sunlight into electricity. Furthermore, Silicon is used in the production of Fiber Optics, which are thin strands of optical fibers that can transmit data over long distances.

Microchips and Semiconductors

Having discussed tungsten, it is time to transition to silicon. Silicon is a key component of microchips and semiconductors, which have revolutionized technology and industry. Microchips and semiconductors are used in a variety of modern gadgets and electronics and are essential for the operation of computers, phones, and other devices. The use of semiconductors has increased drastically in the past few decades, as the demand for more powerful and energy-efficient electronics continues to rise.

Semiconductors are made up of a number of different materials, including silicon, and are typically combined with other materials, such as metals and alloys, to create a desired effect. Silicon is the most widely used material in the semiconductor industry because it has a number of advantageous properties. It is highly resistant to corrosion and oxidation, making it an ideal material for the manufacture of semiconductors. Additionally, it is an excellent electrical conductor, making it an ideal material for use in electrical components.

Solar Cells

Following the unique properties of Tungsten, Silicon has its own set of advantages that make it a popular choice for use in microchips and semiconductors. Its ability to be easily manipulated allows for the creation of smaller components, and its chemical stability makes it a great option for long-term performance. In addition, Silicon is also used in the production of Solar Cells, which are used to capture energy from the sun and convert it into electricity.

Solar cells are formed by layering Silicon with other materials such as phosphorous and boron, and can be used to generate clean energy with no hazardous emissions. They are lightweight and easy to install, making them ideal for powering a variety of applications. In addition, their efficiency has increased over the years, with some cells reaching efficiencies of up to 24%, which is higher than many other renewable sources.

Solar cells are used in a wide range of applications, from powering small consumer devices to large-scale energy production.

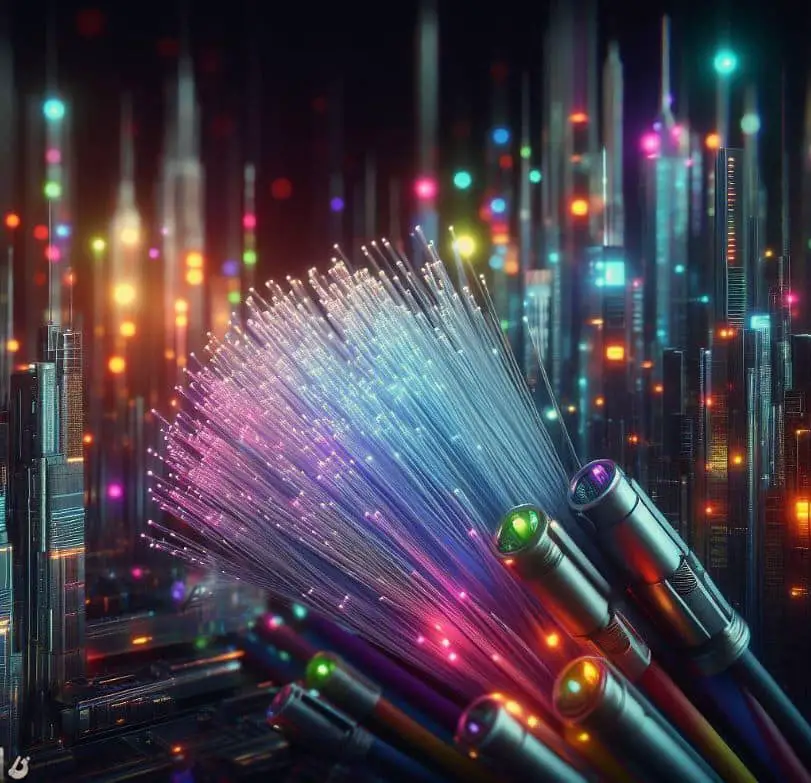

Fiber Optics

Building upon the advancements made with tungsten, silicon has become an integral part of numerous human technological creations. One of the most common applications of silicon is in microchips and semiconductors, which are found in most electronic devices. Another common use of silicon is in solar cells and fiber optics.

Fiber optics is a technology that involves the use of thin glass fibers to transmit light over long distances. This technology is used to create networks for data transmission and communication. It is extremely fast and efficient, and it is much more reliable than traditional copper wires. Fiber optics are made up of strands of glass or plastic that are as thin as human hair. Each strand is capable of carrying up to 10,000 times more data than copper wires. This makes it ideal for high-speed applications such as streaming video and data transmission. Additionally, fiber optics are immune to electromagnetic interference, making them more reliable than copper wires.

Photovoltaic Cells

Following the discovery of tungsten, silicon has become an extremely important material for the production of microchips and semiconductors. It is one of the most widely used materials in the electronics industry due to its excellent electrical properties. Silicon has also been used in the production of photovoltaic cells, which are devices that convert light energy into electricity. Photovoltaic cells are used in a variety of applications, including solar cells, fiber optics, and lighting systems.

When light hits a photovoltaic cell, it is absorbed by the silicon and a current is created. This current is then used to generate electricity. Photovoltaic cells are used in a wide range of applications, from large-scale solar projects to small-scale consumer products. For instance, photovoltaic cells are used to power street lights, solar-powered calculators, and solar-powered homes. They are also used in the development of new energy sources, such as solar energy farms.

In Conclusion, minerals are an important part of the technology industry, and the minerals used vary depending on the application. Copper, gold, lithium, cobalt, graphite, aluminum, zinc, silver, gold, tungsten, and silicon are some of the minerals that are commonly used in technology. These minerals are essential to the production and advancement of technological products, from automobiles to computers. They are used to produce components, including electrical wiring, batteries, and other components. Additionally, these minerals are important for the development of new technologies, such as renewable energy sources. Overall, minerals are essential to the development and advancement of technology in the modern world. Without them, much of the technology we rely on would not exist.